Production Plans Guide

Production plans help you link the invoice/sales order to the bill of materials created to manufacture the same product as the one on the invoice. As a result, the production plan automatically generates one or more manufacturing orders based on the bill of materials included in the production plan, making it easy to convert invoices/sales orders into manufacturing orders.

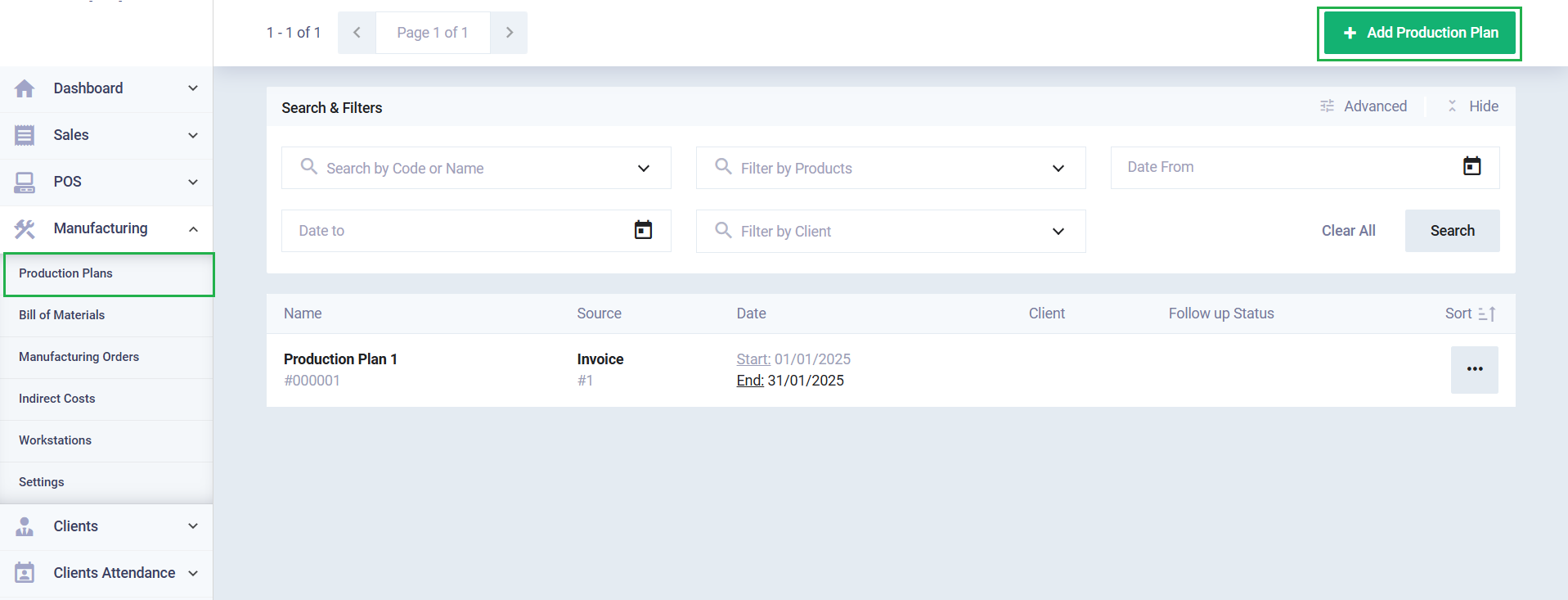

How to create a new production plan?

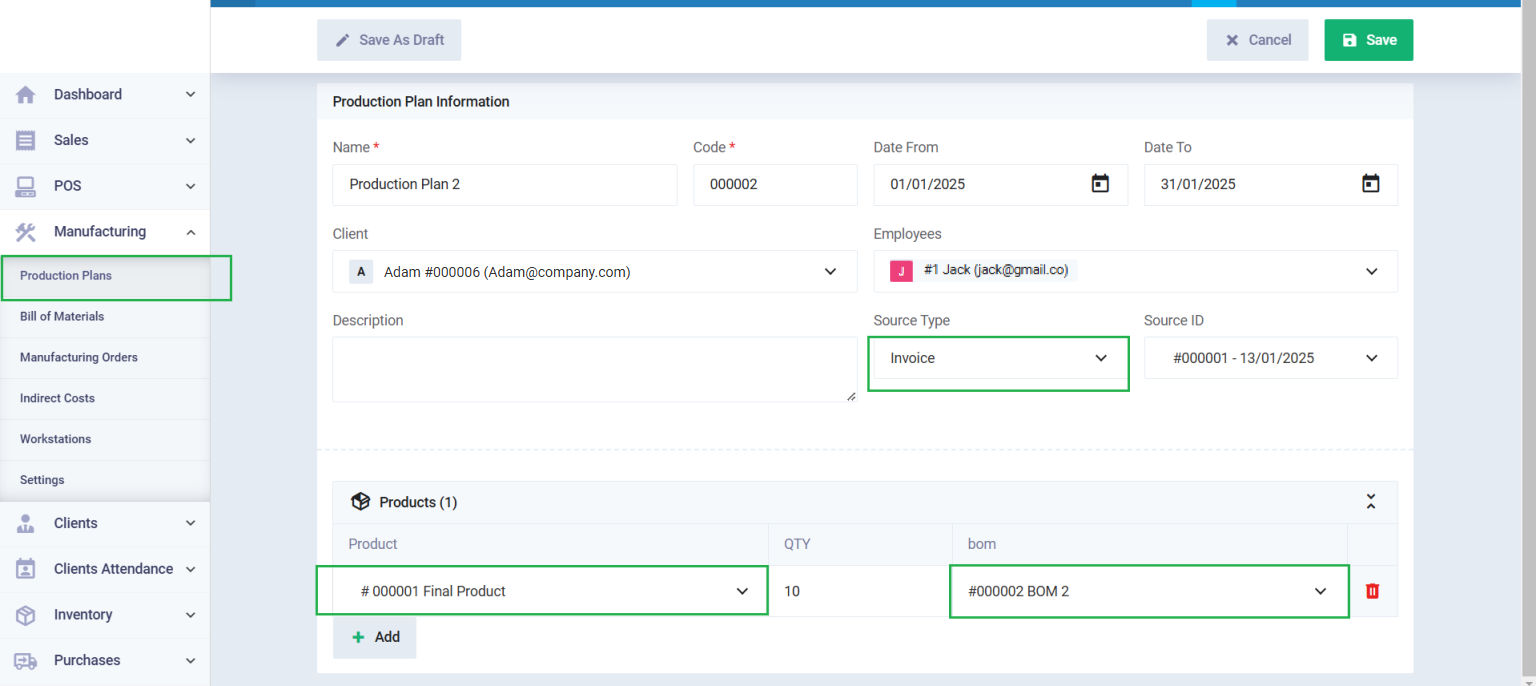

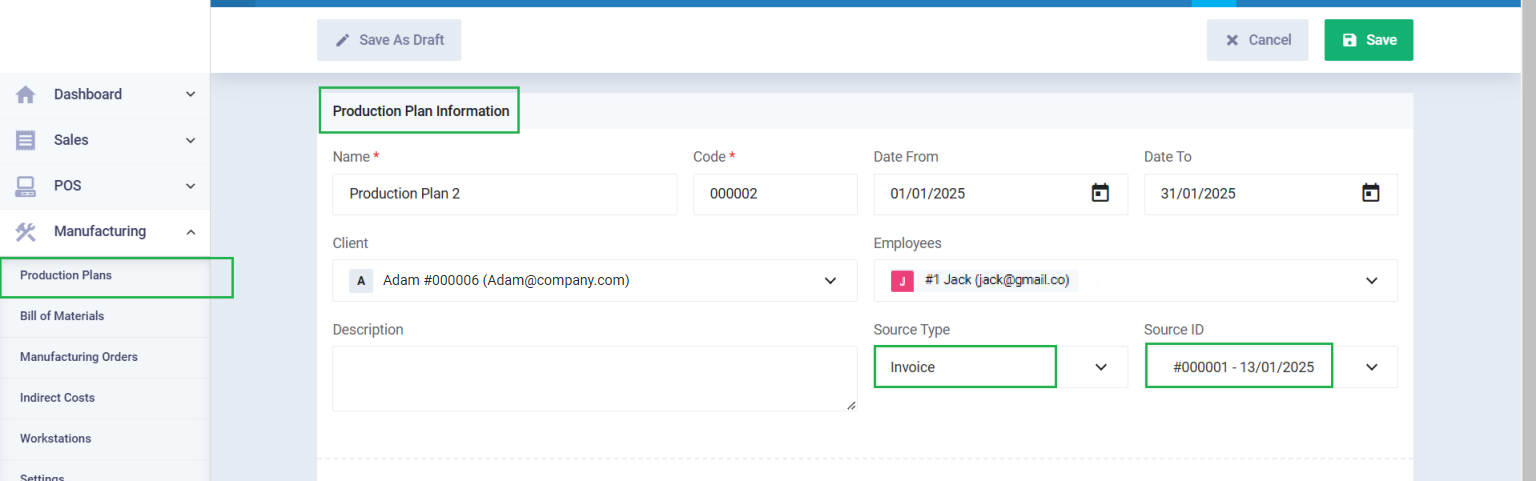

Enter the production plan information:

- Name: Enter a name for the production plan.

- Code: This is a unique automatic number assigned to each production plan, generated by the system.

- Date From: Enter the start date of the production plan.

- Date To: Enter the end date of the production plan.

- Client: Select the client associated with this production plan.

- Employees: Choose the employees responsible for the production plan.

- Description: Enter a description for the production plan.

- Source Type: Choose the source of the production plan (the document it originated from) from the dropdown list, which could be either an invoice or a sales order.

- Source ID: Select the invoice or sales order designated as the source for the production plan.

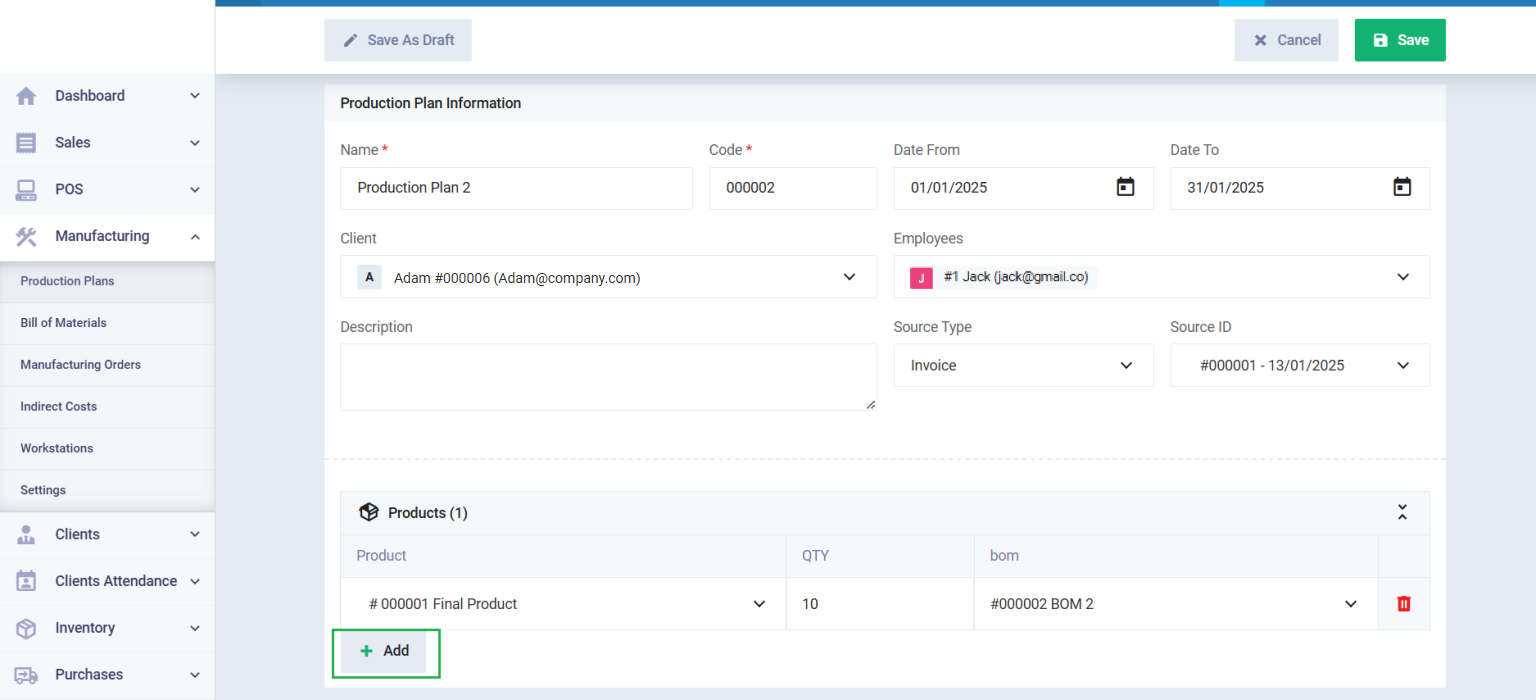

Enter the products information:

Save Production Plans

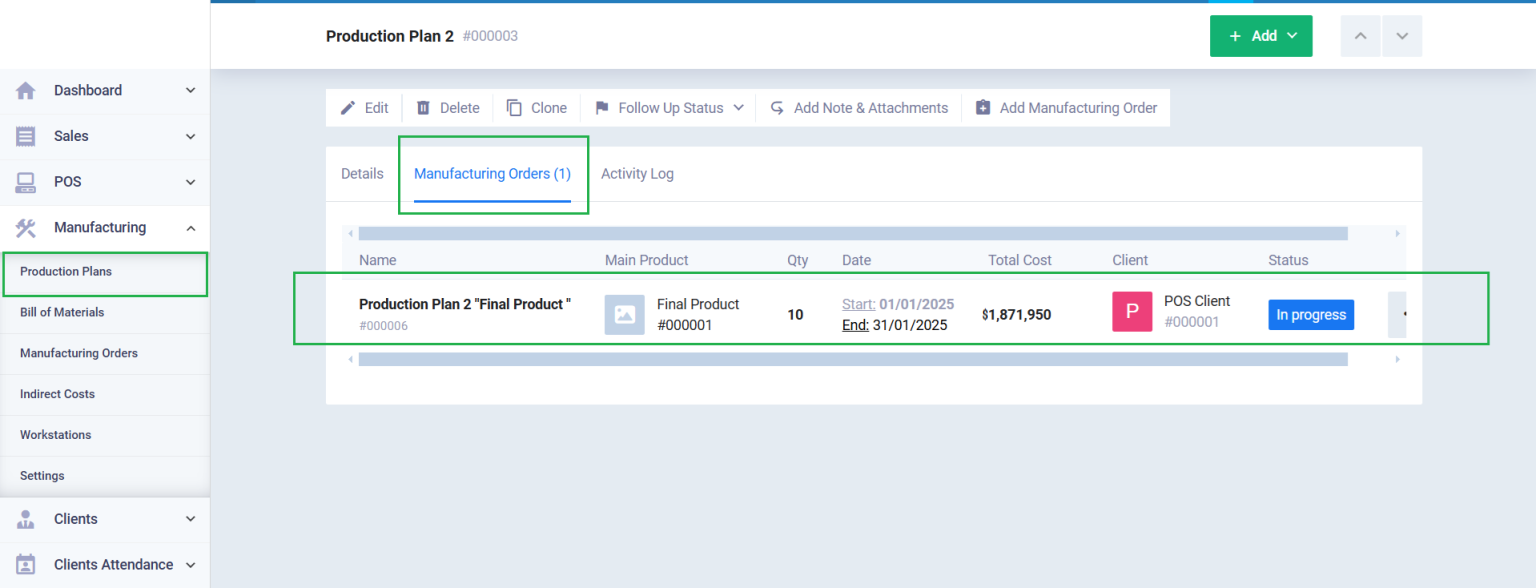

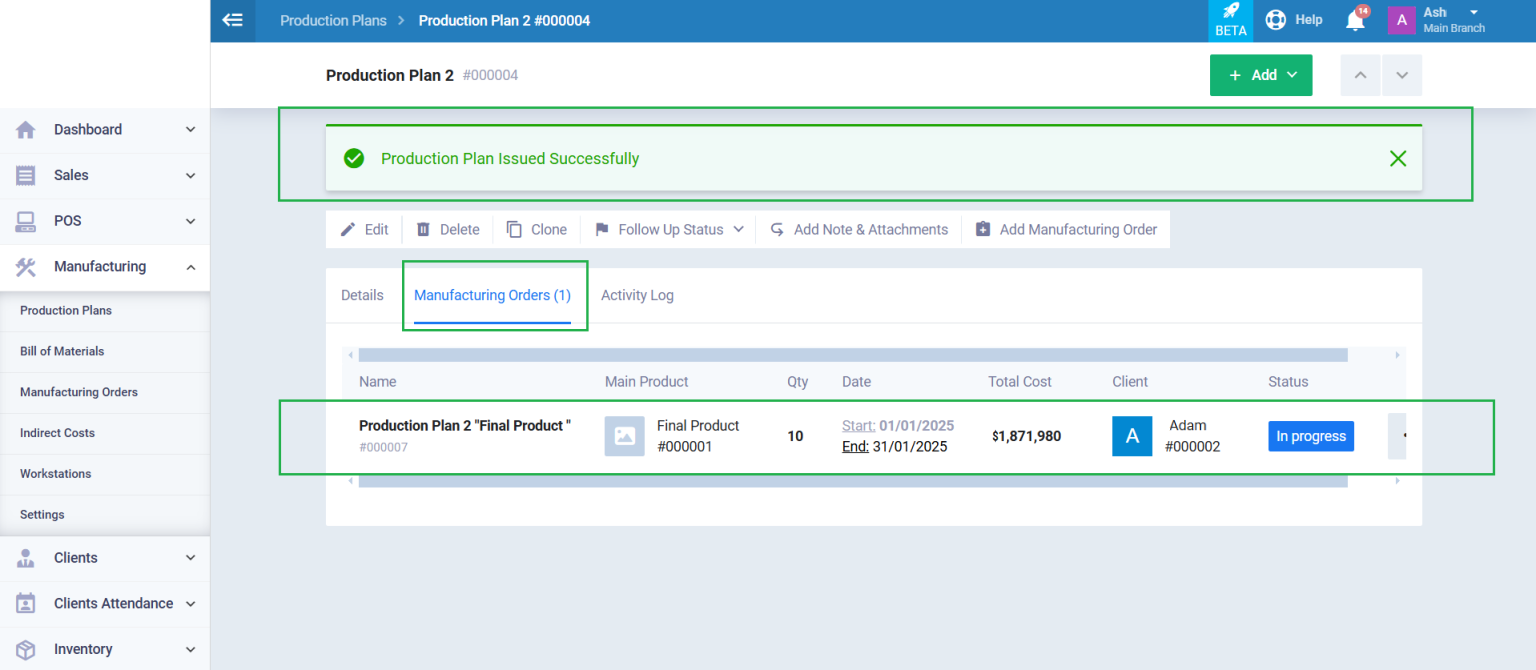

After entering the production plan information, click the “Save” button to save it permanently. As a result, manufacturing orders will be automatically generated from the production plan after saving.

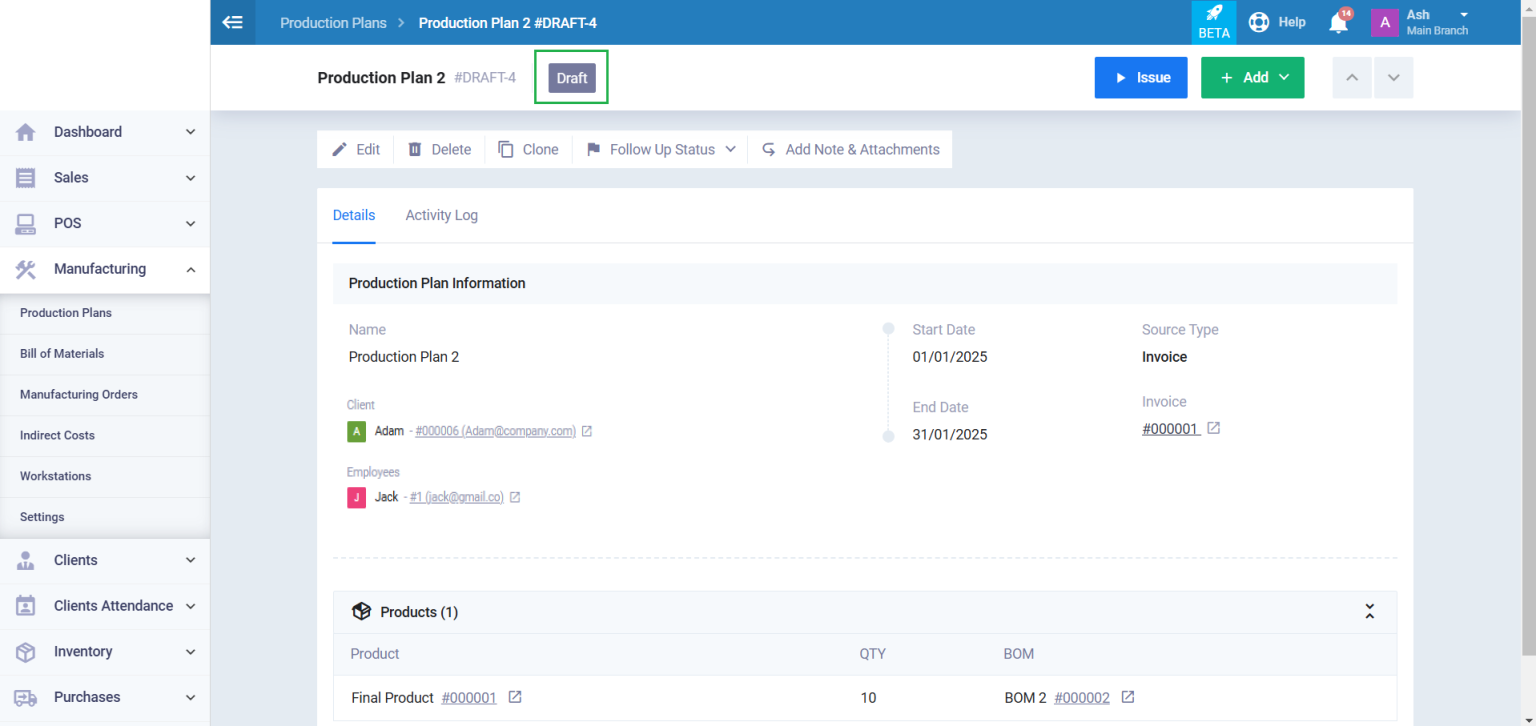

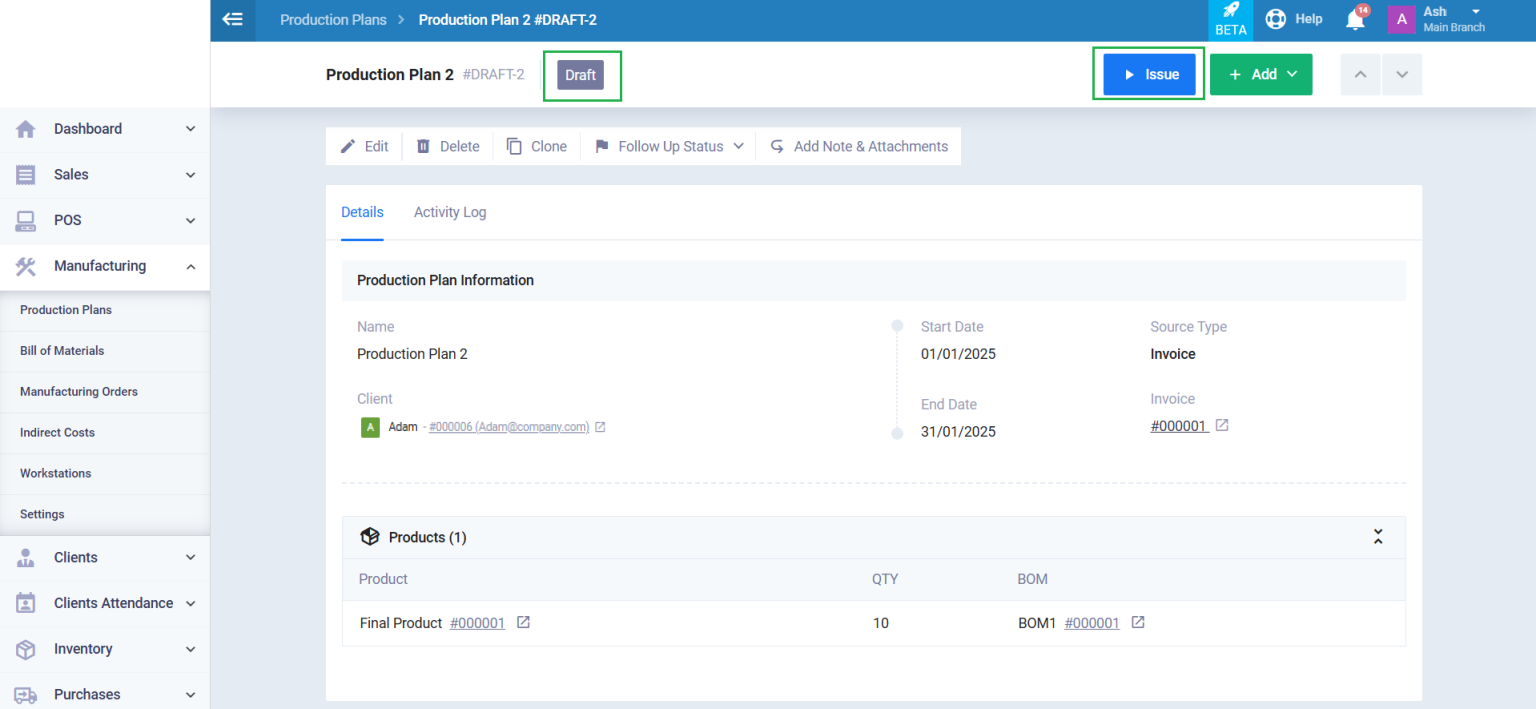

Or click “Save as Draft” if you wish to delay the issuance of manufacturing orders.

When you want to convert the production plan from “Draft” to “Issued” to generate manufacturing orders, open the desired production plan file and click the “Issue” button.

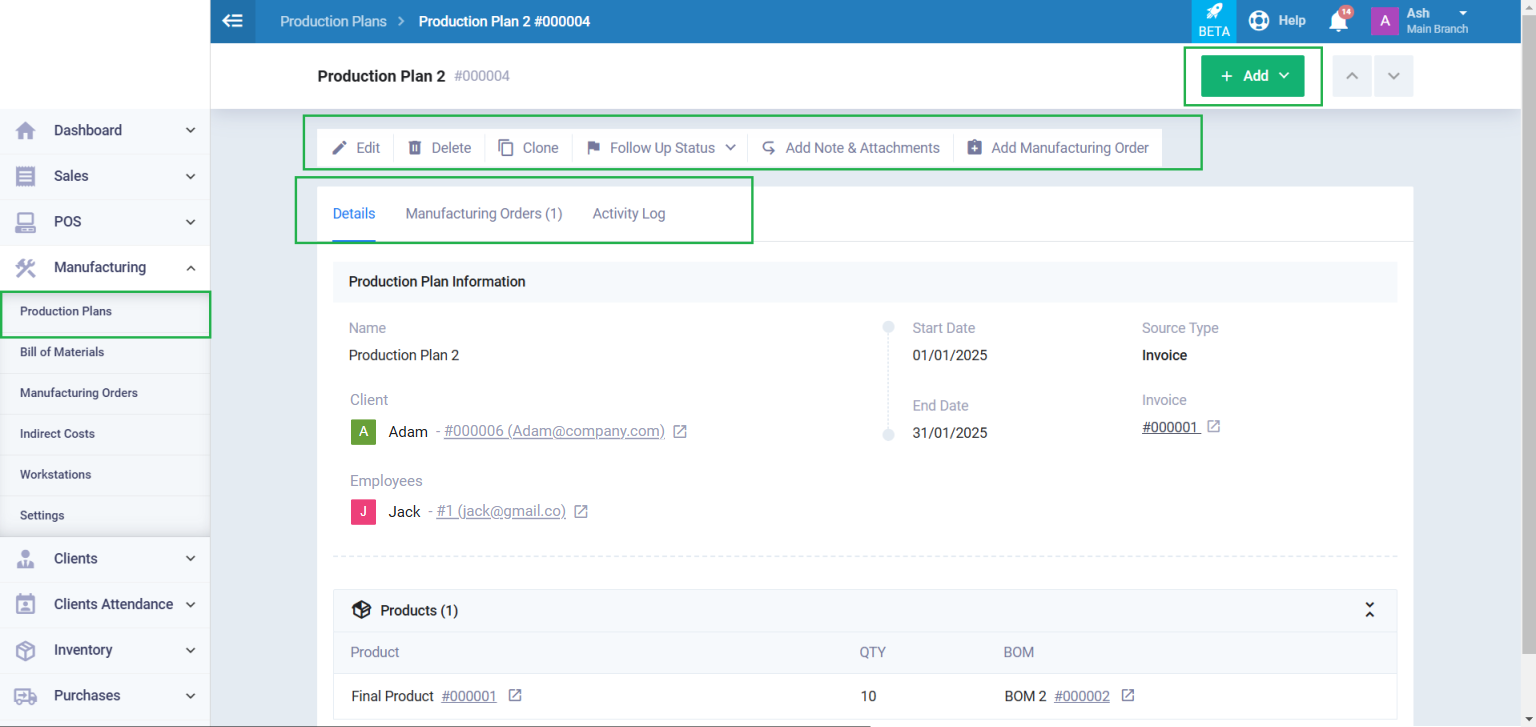

Actions on the Production Plan

After saving the production plan, you can perform several actions such as:

- Edit.

- Clone.

- Delete.

- Setting a follow status for the production plan.

- Adding a note & attachment.

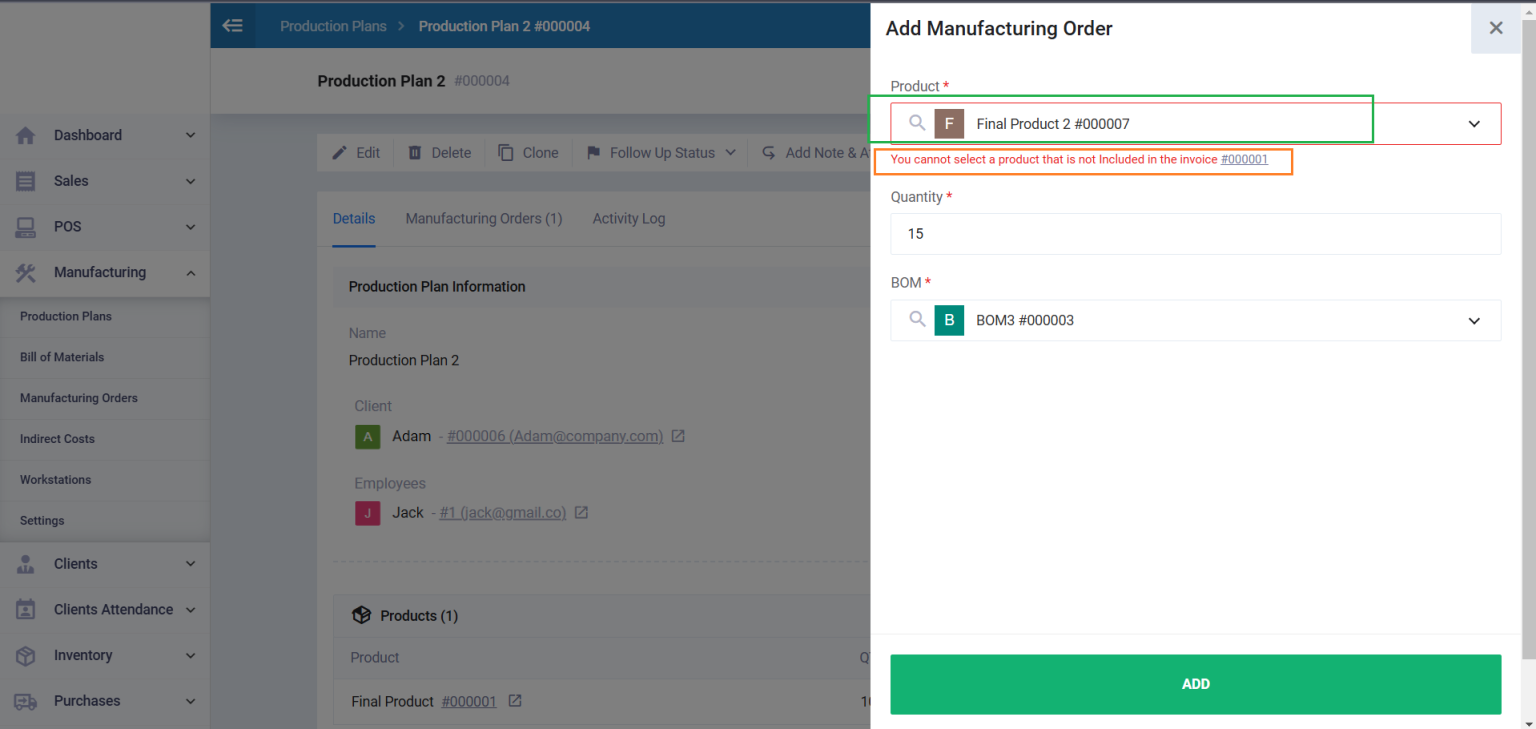

- Adding a manufacturing order to the production plan.

- To add a new product to the manufacturing order that is not included in the invoice linked to the production plan, or to increase the quantity of a product included in the invoice beyond the amount stated in it, you must enable the setting “Add items to the production plan that aren’t in the sales order/invoice” and the setting “A production plan can have more quantities than a sales order/invoice” from the manufacturing settings. If these settings are not enabled, the following error message will appear: “You cannot select a product that is not included in the invoice / You cannot exceed the product quantity in the invoice.”.